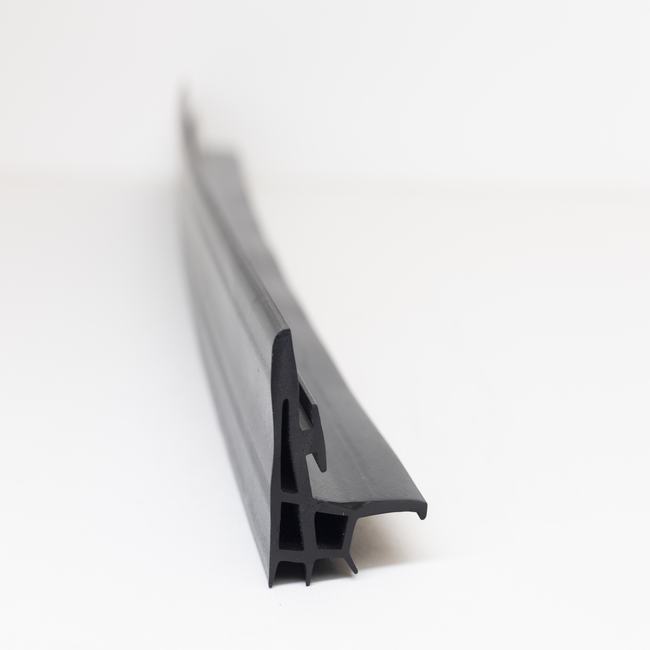

EPDM (Ethylene Propylene Diene Monomer) rubber seals are specialized sealing components made from EPDM rubber material. EPDM is a synthetic elastomer known for its excellent weather resistance, heat resistance, and resistance to UV radiation, ozone, and various chemicals. EPDM rubber seals are commonly used in industrial, automotive, construction, and other applications to provide effective sealing against water, air, dust, and other environmental elements. Here’s a detailed description of EPDM rubber seals:

1. Material Composition:

- EPDM Rubber: EPDM rubber is the primary material used in the production of these seals. It is a synthetic rubber compound composed of ethylene, propylene, and a diene monomer. This composition imparts desirable properties to EPDM, making it an ideal material for seals.

2. Functionality:

- Sealing: The primary function of EPDM rubber seals is to create a reliable and durable seal between two surfaces, preventing the ingress or egress of fluids, gases, contaminants, and environmental factors. They are designed to ensure watertight, airtight, and dustproof seals.

3. Features and Characteristics:

- Weather Resistance: EPDM rubber seals excel in weather resistance, making them ideal for outdoor and long-term applications. They can withstand exposure to sunlight (UV radiation), ozone, and extreme weather conditions.

- Chemical Resistance: EPDM rubber exhibits good resistance to a wide range of chemicals, including acids, alkalis, and polar solvents. This chemical resistance makes it suitable for various industrial environments.

- Heat Resistance: EPDM seals can withstand high temperatures without significant degradation, making them suitable for applications where heat resistance is required.

- Compression Set Resistance: EPDM rubber maintains its shape and sealing properties even after prolonged compression, ensuring long-term performance.

- Flexibility and Elasticity: EPDM rubber is flexible and elastic, allowing it to conform to irregular surfaces and provide a tight seal even under varying conditions.

- Low-Temperature Flexibility: EPDM remains flexible and functional at low temperatures, which is crucial for cold-weather applications.

- Tear Resistance: EPDM rubber is known for its resistance to tearing and abrasion, ensuring durability and a longer service life.

- Electrical Insulation: EPDM rubber serves as an electrical insulator, making it suitable for electrical enclosure gaskets and applications requiring electrical insulation.

4. Applications:

- Automotive: EPDM rubber seals are commonly used in the automotive industry for various sealing applications, including door seals, window seals, weatherstripping, and gaskets for engine components.

- Construction: They find use in the construction industry for sealing doors, windows, roofing, and HVAC systems to ensure weatherproofing, energy efficiency, and insulation.

- Electronics: EPDM rubber seals are employed in electronic enclosures and outdoor electrical installations to provide protection against moisture, dust, and environmental factors.

- Pipelines and Plumbing: EPDM seals are used in pipeline and plumbing systems for water and gas sealing, as well as in sewage and wastewater systems.

- Aerospace: They have applications in the aerospace industry for sealing aircraft components and systems.

- Industrial Equipment: EPDM rubber seals are used in various industrial equipment, machinery, pumps, and tanks for sealing purposes.

- Marine: They are used in marine applications to seal hatches, doors, and access points on boats and ships, providing water and weather resistance.

In summary, EPDM rubber seals are versatile and reliable sealing components known for their durability and resistance to a wide range of environmental factors. They are essential for maintaining watertight, airtight, and dustproof seals in various industrial and commercial applications. Proper selection, installation, and maintenance of EPDM rubber seals are crucial for ensuring their long-lasting effectiveness.