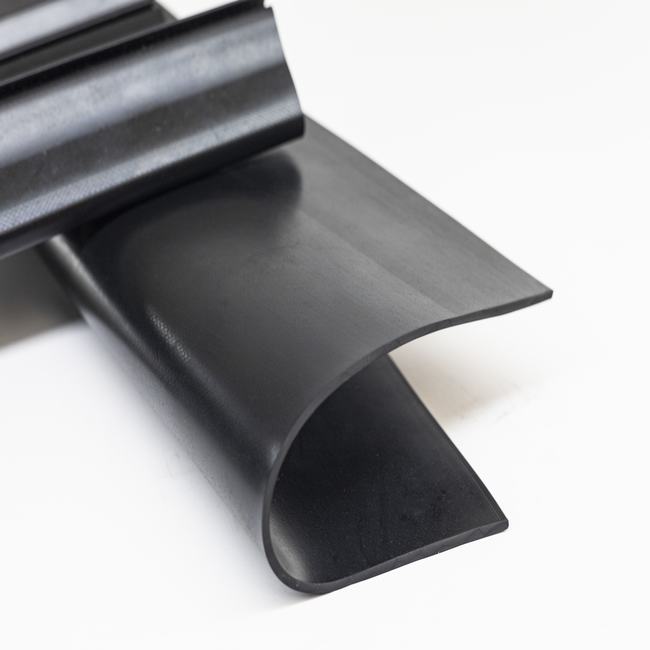

GRP pipe seals, also known as fiberglass reinforced plastic (GRP) pipe seals or gasket seals, are integral components used in the installation and maintenance of GRP piping systems. These seals play a crucial role in ensuring the leak-free and secure connection of GRP pipes, which are commonly employed in a wide range of industrial applications, including chemical processing, water and wastewater management, oil and gas transmission, and more. To provide a comprehensive understanding, let’s delve into a detailed description of GRP pipe seals:

1. Material Composition:

- Fiberglass Reinforced Plastic (GRP): The primary component of GRP pipe seals is fiberglass-reinforced plastic. GRP is a composite material made of a matrix of resin, typically polyester or epoxy, reinforced with fiberglass strands. This combination results in a material that is strong, durable, corrosion-resistant, and well-suited for use in various environmental conditions.

2. Functionality:

- Sealing: The primary function of GRP pipe seals is to create a secure and leak-proof seal at the joints and connections of GRP pipes. This sealing capability is essential to prevent the loss of fluids, gases, or chemicals from the pipeline and to maintain the integrity of the system.

3. Features and Characteristics:

- Chemical Resistance: GRP pipe seals exhibit excellent resistance to a wide range of chemicals, acids, and corrosive substances. This property ensures that the seals remain intact and effective even when exposed to aggressive media.

- Corrosion Resistance: GRP materials inherently resist corrosion and are not susceptible to rust or degradation, even in harsh environments.

- High Strength: GRP pipe seals are known for their high tensile strength and can withstand mechanical stress and pressure variations, making them suitable for various industrial applications.

- UV Resistance: GRP materials are UV-resistant, ensuring that the seals maintain their structural integrity when exposed to sunlight.

- Temperature Tolerance: These seals can endure a broad temperature range, making them suitable for both hot and cold fluid transport applications.

- Longevity: GRP pipe seals are designed to have a long service life, providing durable sealing solutions that require minimal maintenance over time.

- Dimensional Stability: They maintain their shape and sealing properties even under changing temperatures and pressures, thanks to their excellent dimensional stability.

4. Applications:

- Chemical Processing: GRP pipe seals are widely used in chemical plants, where the resistance to corrosive chemicals is crucial.

- Water and Wastewater Management: They play a critical role in water treatment facilities, sewage systems, and desalination plants.

- Oil and Gas Industry: GRP pipe seals are utilized in pipelines for the transport of oil, gas, and petrochemical products.

- Marine and Offshore: Their corrosion resistance makes them suitable for marine applications and offshore installations.

- Infrastructure and Construction: They are used in various infrastructure projects, such as bridges, tunnels, and industrial facilities.

5. Installation and Maintenance:

- Proper installation techniques are essential to ensure the effective functioning of GRP pipe seals. This includes cleaning and preparing the pipe ends, applying sealant or adhesive as needed, and securely fitting the seals in place.

- Routine inspections and maintenance are recommended to detect and address any signs of wear or damage to the seals, ensuring continued reliability.

In summary, GRP pipe seals are indispensable components in GRP piping systems, offering exceptional sealing capabilities, chemical resistance, longevity, and durability. Their ability to maintain leak-free connections in demanding industrial environments makes them a preferred choice for critical applications across various industries. Proper selection, installation, and maintenance of GRP pipe seals are essential to ensure the integrity and efficiency of GRP piping systems.